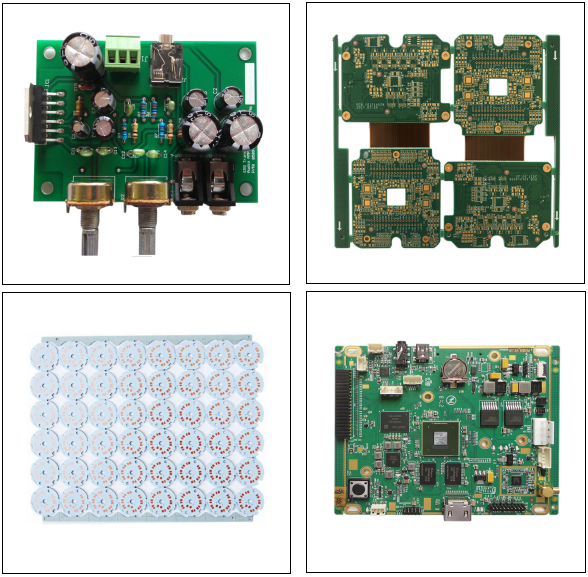

Tuam Tshoj OEM PCB Enclosure Thiab Sib Tsoo Rau Thaum Muaj Xwm Ceev Nres Hloov, Electronics PCB Ntau Lawm Turnkey Kev Pabcuam suav nrog Kev Pabcuam thiab Kev Xeem, Ua tiav Rau Electronics PCBs

PRODUCT SPECIFICATION:

| Khoom siv hauv paus: | FR4-TG 140 | Nto tiav: | HASL (Lead Free) |

| PCB Thickness: | 1.6mm ib | Solder Mask: | Xiav |

| PCB Loj: | 90*160mm | Silkscreen: | Dawb |

| Txheej suav: | 2/L | Cu Thickness | 35um (1oz) |

| Mounting Hom: | SMT + DIP | SMT pob | 0201, BGA, QFN |

| Kev Pab Cuam | AOI, X-Ray, Function Test | Yam khoom | Kev sib dhos Hoobkas |

TurnkeyKev pab:

1. PCB fabrication

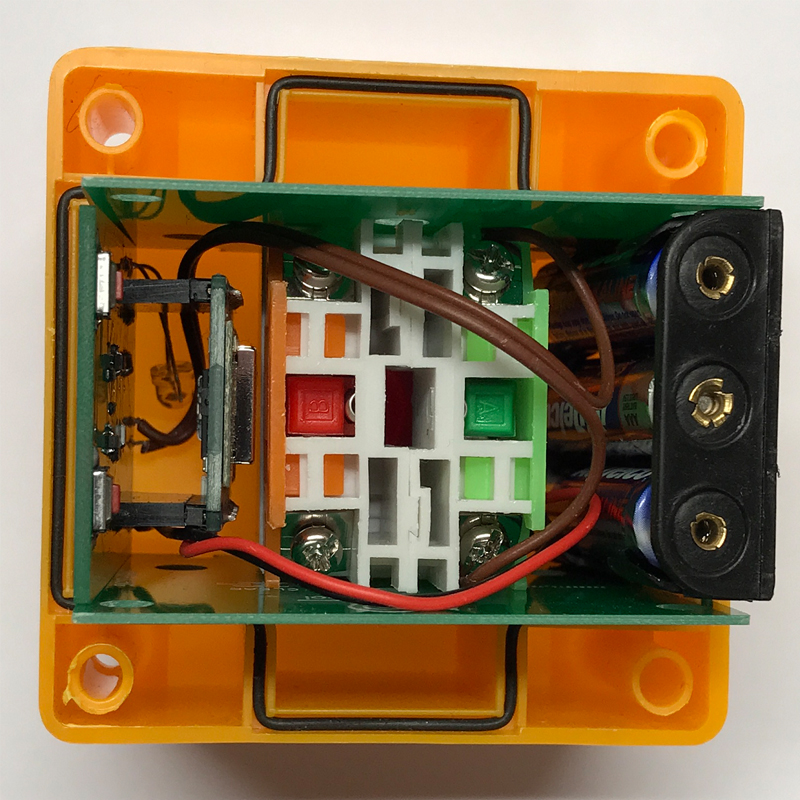

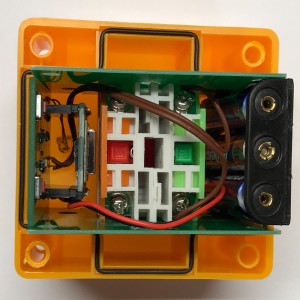

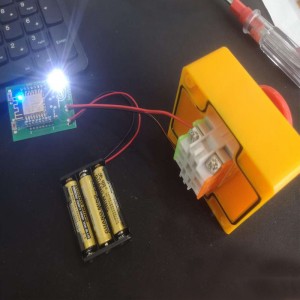

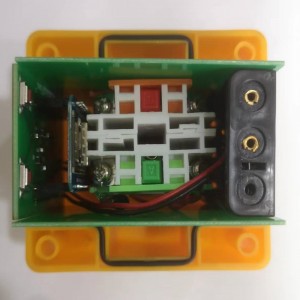

2. Turnkey PCBA: PCB + khoom + SMT thiab los ntawm lub qhov sib dhos + enclosure molding & vaj tse

Cov khoom tseem ceeb:

Peb qhov zoo:

1, programming thiabFkuaj tsis tau

2, IPC-A-610E tus qauv, E-test, X-ray, AOI xeem, QC, 100% lom zemckev xeem.

3, Kev pabcuam tshaj lij.ISO SMT thiab los ntawm qhov sib dhos, dhau 10 xyoo dhau los.

4,Daim ntawv pov thawj: 94v-0, CE, SGS, FCC, RoHS, ISO9001: 2008, ISO14001

5,Lub sijhawm lav rau PCBA: 2 xyoos.

PCBA PROCESSING CABILITY:

| Turnkey PCBA | PCB + cov khoom siv khoom + kev sib dhos + pob |

| Cov ntsiab lus sib dhos | SMT thiab Thru-qhov, PCB enclosure sib dhos |

| Lub Sijhawm Lead | Qauv:10-12ua haujlwmhauvhnub.Kev txiav txim loj:18~20worhuab taishnub |

| Kev ntsuam xyuas ntawm cov khoom | Flying Probe Test,E-Tsim,X-ray Inspection, AOI Test, Functional Test |

| Ntau | Min kom muaj nuj nqis: 1pcs.Prototype, kev txiav txim me me, kev txiav txim loj |

| Cov ntaub ntawvhom | PCB: Gerber cov ntaub ntawv (CAM, PCB, PCBDOC) |

| Cheebtsam: Bill of Materials (BOM list) | |

| Sib dhos: Xaiv&Muab cov ntaub ntawv, Sib dhos daim duab | |

| PCB Vaj Huam Sib Luag Loj | Qhov loj me: 0.25 * 0.25 nti (6 * 6mm) |

| Loj: 20 * 20 nti (500 * 500mm) | |

| PCB Solder Hom | Dej Soluble Solder Paste, RoHS tsis muaj txhuas |

| Cov ntsiab lus tseem ceeb | Passive Down rau 01005qhov loj |

| BGA thiabQFN Rau Chip | |

| Ob chav sided SMT sib dhos | |

| Fine Pitch rau 0.8mils | |

| Kev tshem tawm thiab hloov | |

| Cov khoom siv pob | Txiav daim kab xev, Tube, Reels, Loose Parts |

PCB kev ua haujlwm muaj peev xwm:

| 1 | Txheej | 1-32Txheej |

| 2 | Board khoom hom | FR4,Ceramic substrate board,aluminium raws board, high-Tg, Rogers thiab lwm yam |

| 3 | Compound khoom lamination | 4 rau 6 txheej |

| 4 | Qhov siab tshaj plaws | 600x1 ua200mm ib |

| 5 | Board thickness npog | 0.2-6.00 hli |

| 6 | Yam tsawg kawg kab dav | 3mil ua |

| 7 | Yam tsawg kawg ntawm kab | 3mil ua |

| 8 | Txheej txheej tooj liab thickness | 8.75-175 µm |

| 9 | Sab hauv txheej tooj liab thickness | 17.5-175 µm |

| 10 | Drilling qhov taub (mechanical laum) | 0.25-6.00 hli |

| 11 | Tiav qhov taub (mechanical laum) | 0.20-6.00 hli |

| 12 | Qhov txoj kab uas hla tolerance (mechanical laum) | 0.05 hli |

| 13 | Qhov txoj hauj lwm kam rau ua (mechanical laum) | 0.075 hli |

| 14 | Laser laum qhov loj | 0.10 hli |

| 15 | Board thickness thiab qhov sib piv | 10:1 |

| 16 | Solder mask hom | Ntsuab, Daj, Dub, Ntshav, Xiav, Dawb thiab Liab |

| 17 | Yam tsawg kawg nkaus solder mask | Ø 0.10 hli |

| 18 | Yam tsawg kawg nkaus ntawm lub ntsej muag lub ntsej muag sib cais lub nplhaib | 0.05 hli |

| 19 | Solder daim npog qhov ncauj roj ntsaws qhov taub | 0.25-0.60 hli |

| 20 | Impedance tswj kam rau ua | ± 10% |

| 21 | Nto tiav | HASL (Lead Free), ENIG, immersion nyiaj, kub plating, immersion tin thiab kub ntiv tes |

Kev xa khoom sai:

PCBIn 12 teev

PCBA Hauv 3 Hnub

Daim ntawv thov cov khoom tseem ceeb:

* Cov khoom kho mob

* Cov khoom siv tsheb

* Cov khoom lag luam

* Cov khoom siv sib txuas lus (AVL / GPS / GSM Devices)

* Consumer Electronics.

Cov txheej txheem sib dhos PCB:

* Kev Tswj Xyuas Txoj Haujlwm

Cov ntaub ntawv PCB → DCC → Program Organizing → Optimization → Checking

* Kev tswj hwm SMT

PCB Loader → Screen Printer → Xyuas → SMD Qhov Chaw → Kuaj → Cua Reflow → Kev Pom Zoo → AOI → Khaws

* Kev Tswj Xyuas PCBA

THT → Soldering Wave (Kev Taw Qhia Vuam) → Kev Tshawb Fawb Lub Zeem Muag → ICT → Flash → FCT → Kev Tshawb Fawb → Pob → Xa khoom

PHILIFAST muab koj qhov zoo tshaj plaws PCB tsim thiab sib dhos kev paub