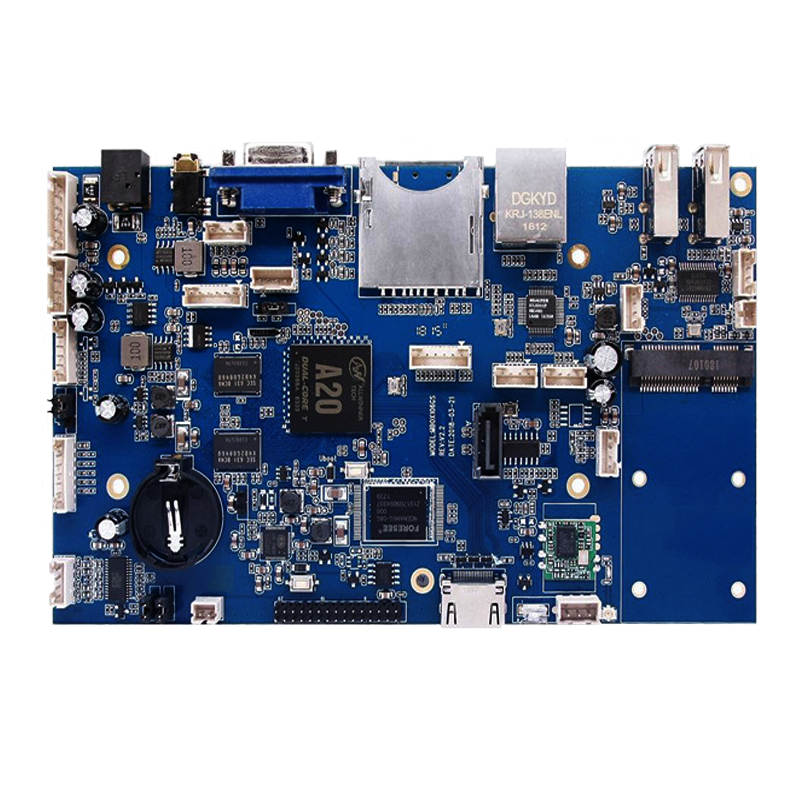

Turnkey PCB Assembly Electronic Printed Pcb Circuit Board Chaw tsim tshuaj paus nyob rau hauv Suav teb PCBA boards

PRODUCT SPECIFICATION:

| Khoom siv hauv paus: | FR4-TG 140 | Nto tiav: | HASL (Lead Free) |

| PCB Thickness: | 1.6mm ib | Solder Mask: | Xiav |

| PCB Loj: | 90*160mm | Silkscreen: | Dawb |

| Txheej suav: | 2/L | Cu Thickness | 35um (1oz) |

| Mounting Hom: | SMT + DIP | SMT pob | 0201, BGA, QFN |

| Kev Pab Cuam | AOI, X-Ray, Function Test | Yam khoom | Kev sib dhos Hoobkas |

TurnkeyKev pab:

1. PCB fabrication

2. Turnkey PCBA: PCB + khoom + SMT thiab los ntawm lub qhov sib dhos + enclosure molding & vaj tse

Cov khoom tseem ceeb:

Peb qhov zoo:

1, programming thiabFkuaj tsis tau

2, IPC-A-610E tus qauv, E-test, X-ray, AOI xeem, QC, 100% lom zemckev xeem.

3, Kev pabcuam tshaj lij.ISO SMT thiab los ntawm qhov sib dhos, dhau 10 xyoo dhau los.

4,Daim ntawv pov thawj: 94v-0, CE, SGS, FCC, RoHS, ISO9001: 2008, ISO14001

5,Lub sijhawm lav rau PCBA: 2 xyoos.

PCBA PROCESSING CABILITY:

| Turnkey PCBA | PCB + cov khoom siv khoom + kev sib dhos + pob |

| Cov ntsiab lus sib dhos | SMT thiab Thru-qhov, PCB enclosure sib dhos |

| Lub Sijhawm Lead | Qauv:10-12ua haujlwmhauvhnub.Kev txiav txim loj:18~20worhuab taishnub |

| Kev ntsuam xyuas ntawm cov khoom | Flying Probe Test,E-Tsim,X-ray Inspection, AOI Test, Functional Test |

| Ntau | Min kom muaj nuj nqis: 1pcs.Prototype, kev txiav txim me me, kev txiav txim loj |

| Cov ntaub ntawvhom | PCB: Gerber cov ntaub ntawv (CAM, PCB, PCBDOC) |

| Cheebtsam: Bill of Materials (BOM list) | |

| Sib dhos: Xaiv&Muab cov ntaub ntawv, Sib dhos daim duab | |

| PCB Vaj Huam Sib Luag Loj | Qhov loj me: 0.25 * 0.25 nti (6 * 6mm) |

| Loj: 20 * 20 nti (500 * 500mm) | |

| PCB Solder Hom | Dej Soluble Solder Paste, RoHS tsis muaj txhuas |

| Cov ntsiab lus tseem ceeb | Passive Down rau 01005qhov loj |

| BGA thiabQFN Rau Chip | |

| Ob chav sided SMT sib dhos | |

| Fine Pitch rau 0.8mils | |

| Kev tshem tawm thiab hloov | |

| Cov khoom siv pob | Txiav daim kab xev, Tube, Reels, Loose Parts |

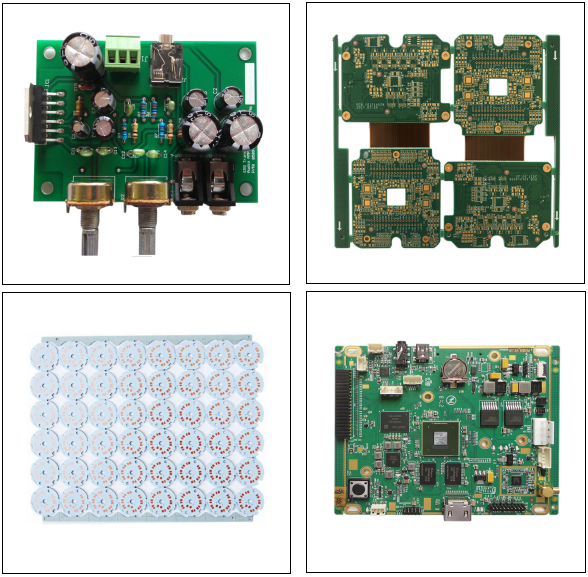

PCB kev ua haujlwm muaj peev xwm:

| 1 | Txheej | 1-32Txheej |

| 2 | Board khoom hom | FR4,Ceramic substrate board,aluminium raws board, high-Tg, Rogers thiab lwm yam |

| 3 | Compound khoom lamination | 4 rau 6 txheej |

| 4 | Qhov siab tshaj plaws | 600x1 ua200mm ib |

| 5 | Board thickness npog | 0.2-6.00 hli |

| 6 | Yam tsawg kawg kab dav | 3mil ua |

| 7 | Yam tsawg kawg ntawm kab | 3mil ua |

| 8 | Txheej txheej tooj liab thickness | 8.75-175 µm |

| 9 | Sab hauv txheej tooj liab thickness | 17.5-175 µm |

| 10 | Drilling qhov taub (mechanical laum) | 0.25-6.00 hli |

| 11 | Tiav qhov taub (mechanical laum) | 0.20-6.00 hli |

| 12 | Qhov txoj kab uas hla tolerance (mechanical laum) | 0.05 hli |

| 13 | Qhov txoj hauj lwm kam rau ua (mechanical laum) | 0.075 hli |

| 14 | Laser laum qhov loj | 0.10 hli |

| 15 | Board thickness thiab qhov sib piv | 10:1 |

| 16 | Solder mask hom | Ntsuab, Daj, Dub, Ntshav, Xiav, Dawb thiab Liab |

| 17 | Yam tsawg kawg nkaus solder mask | Ø 0.10 hli |

| 18 | Yam tsawg kawg nkaus ntawm lub ntsej muag lub ntsej muag sib cais lub nplhaib | 0.05 hli |

| 19 | Solder daim npog qhov ncauj roj ntsaws qhov taub | 0.25-0.60 hli |

| 20 | Impedance tswj kam rau ua | ± 10% |

| 21 | Nto tiav | HASL (Lead Free), ENIG, immersion nyiaj, kub plating, immersion tin thiab kub ntiv tes |

Kev xa khoom sai:

PCBIn 12 teev

PCBA Hauv 3 Hnub

Daim ntawv thov cov khoom tseem ceeb:

* Cov khoom kho mob

* Cov khoom siv tsheb

* Cov khoom lag luam

* Cov khoom siv sib txuas lus (AVL / GPS / GSM Devices)

* Consumer Electronics.

Cov txheej txheem sib dhos PCB:

* Kev Tswj Xyuas Txoj Haujlwm

Cov ntaub ntawv PCB → DCC → Program Organizing → Optimization → Checking

* Kev tswj hwm SMT

PCB Loader → Screen Printer → Xyuas → SMD Qhov Chaw → Kuaj → Cua Reflow → Kev Pom Zoo → AOI → Khaws

* Kev Tswj Xyuas PCBA

THT → Soldering Wave (Kev Taw Qhia Vuam) → Kev Tshawb Fawb Lub Zeem Muag → ICT → Flash → FCT → Kev Tshawb Fawb → Pob → Xa khoom

PHILIFAST muab koj qhov zoo tshaj plaws PCB tsim thiab sib dhos kev paub